Our “pmi PE” polyethylene plastic profiles consist of high-density polyethylene (HDPE), UV-inhibited pigment systems, foaming compounds and selected process additives.

The high-density polyethylene raw material utilized in pmi PE is derived from recycled post-consumer bottle waste such as milk containers. This material is cleaned in a decontamination process to a high purity level, which removes contaminants such as food residue, paper and adhesives. It is then compounded into a rigid board stock material with the resulting finished product containing over 90% recycled post-consumer waste by weight.

Because pmi PE is made with a single, purified polymer, it is manufactured to exacting, reproducible specifications. It has exceptional resistance to moisture, corrosive substances, insects and other environmental stresses. It does not absorb moisture, therefore it will not rot, splinter or crack. Additionally, pmi PE requires no waterproofing, staining or similar maintenance when used in many exterior applications.

pmi PE is manufactured in many dimensional lumber sizes, shapes and colors. Planks, rails, slats, tongue and groove and many specialty profiles are available. The product comas in many wood tone and popular colors, such as: Cedar, Weathered Redwood, Light Oak, Gray, White, Green, Dark Brown and Black. Custom Colors can be produced on a commercial scale.

pmi PE has excellent weathering resistance. Accelerated weathering tests in accordance with ASTM E838, indicates that pmi PE is very color stable, with a reflectance of .91 on scale of 0-100, after approximately 1 million Langleys of exposure (about three years in most of N. America). This stability is achieved with the use of pigment systems that are resistant to breakdown by radiant energy. Hindered amino polymer stabilizers are also Inc. in the lumber compound to resist degradation of physical properties.

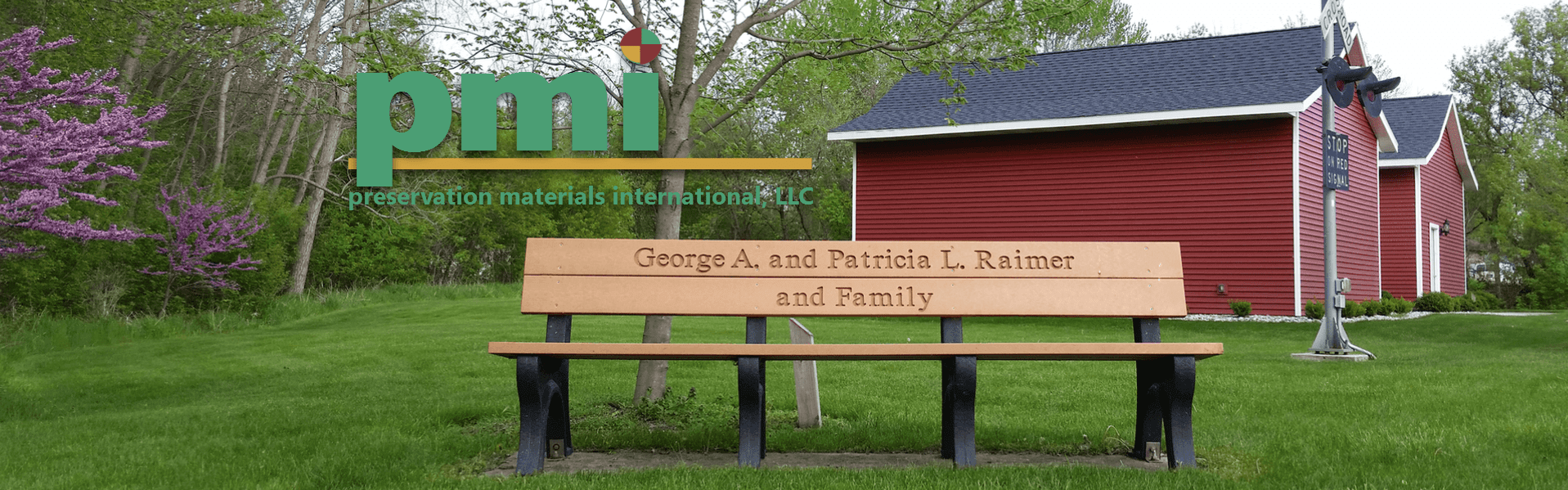

pmi PE is used in many conventional wood lumber applications, and is often the product of choice for exterior applications where weathering resistance and low maintenance are required.

Used in both commercial and residential applications pmi PE is well suited for decking, flooring, furnishings, fencing, marine products, lawn and garden items, bridges, playground and agricultural equipment, sound and traffic barriers.

This type of lumber product has less rigidity and greater elongation than wood lumber. Therefore, it is not recommended for use as a true structure.

As noted above, pmi PE has a lower modulus of elasticity (or beam strength) than wood lumber. It therefore should not be employed as a structural component, unless an engineering study indicates that its use is appropriate.

When installing pmi PE, design consideration should be given to expansion and contraction. As noted in the mechanical property data, this material will expand and contract with temperature variation.

For example, a six foot beam of pmi PE may expand or contract ¼” over a 50 degree temperature change. II a beam is installed at 50° F and temperature increase to 100° F, the beam will expand in the length dimension approximately ‘A”. To determine the effect of temperature change for a specific application, use the formula: .00007 x length of board in inches x degrees F of temperature change = inches of expansion or contraction in length dimension.

To accommodate this movement adequate spacing should be given between adjacent or abutting members. This will allow for the expansion or contraction, without stressing or backing out fasteners.

pmi PE can be fabricated and installed using standard woodworking tools. You may have to use a lower speed with your router or planer/jointer to prevent “gumming up” of the router bit or the planer/jointer knives. Carbide tipped bits and blades are recommended. Always use tools according to manufacturer’s instructions and wear protective clothing and safety glasses for your safety.

.

pmi PE is manufactured in continuous extrusions, and can be made to virtually any length. Many profiles are stocked in 12’ and 16’ lengths. Popular lumber cross sections include:

| 1-inch thick: | 2-inch thick: | 3-inch thick: | 4-inch thick: | 6-inch thick: |

|---|---|---|---|---|

| 1 x 3 | 2 x 4 | 3 x 4 | 4 x 4 | 6 x 6 |

| 1 x 4 | 2 x 6 | 4 x 6 | 6 x 8 | |

| 1 x 5 | 2 x 8 | |||

| 1 x 6 | 2 x 10 | |||

| 1 x 6 t/g* | 2 x 12 | |||

| 1 x 12 t/g | ||||

| 1 x 18 |

Custom lengths can be extruded to minimize scrap and cost Custom profiles of various shapes and sizes are developed and manufactured by pmi Inc. Customers can design proprietary profiles for production.

pmi PE is manufactured with a twenty-five-year limited warranty. The product is warranted not to rot, split, crack, or splinter during this period. (See Full Warranty details.).

pmi PE is unaffected by most corrosive substances, and will not absorb moisture or promote bacterial growth. To maintain the original finish, clean the lumber with soap and water. A low-velocity power wash can also be very effective in keeping your product look great. No sealing or painting is required; as a rule, paint will not adhere to pmi PE.

Graffiti can be cleaned from the plastic lumber with the use of a conventional all-purpose cleaner or petroleum based cleaner.

If the skin or surface layer of lumber becomes marred or blemished, please contact us so we can assist you with the repair.

pmi PE is impervious to paint and most adhesives; therefore these materials are not recommended for use with the product. The product has a melt temperature of approximately 620°F. It has a higher flash point than wood, and it must be exposed to a severe combustion source for a longer period than wood to ignite the product. But like wood, when exposed to a combustion source for a long enough period, it will burn. Should a flame occur, extinguishing media should be dry chemical, foam, carbon dioxide or water spray, water should be applied from a fogging nozzle. Additionally, flame retardant grades of pmi PE can be compounded when required.

For Additional Technical Data, Specifications and Application information please contact us by calling 616-527-7566 or email us: [email protected]

| Mechanical Properties | ASTM Standard | Average Value |

|---|---|---|

| Density/Specific Gravity (g/cc) | D6111 | 0.7064 |

| Density/Specific Gravity (pcf) | D6111 | 44.1 |

| Water Absorption | D570 | <0.1 |

| Compression – Secant Modulus (psi) | D6108 | 104,420 |

| Compression – Stress @ 3% Strain (psi) | D6108 | 1,999 |

| Flexure, Secant Modulus | D6109 | 113,595 |

| Fastener Pullout Failure Load (lbs) | D6117 | 1,522 |

| Fastener Shear Maximum Load (lbs) | D6117 | 769 |

| Coefficient of Friction – Embossed (Dry) Rubber | D2047 | 0.90 |

| Coefficient of Friction – Embossed (Wet) Rubber | D2047 | 0.97 |

| Thermal Expansion (standard) (in/in/°F) | D6341 | 4.965 x 10-5 |

| Thermal Expansion (decking) (in/in/°F) | D6341 | .4.33 x 10-5 |

| Flame Spread | E84 | Class C |

Technical, specification, and application information is available from pmi by calling us at 616-527-7566.

Applications include:

- Bleacher and Locker Room seating

- Equipment Storage systems

- Weather and corrosion resistant OEM parts

- Casual Furniture

- Agricultural equipment and partitions

- Lawn and garden products

- Transportation equipment

- Landscape timbers

- Decking and porch flooring

- Road signage posts

- Docks, piers, bridges, boardwalks

- Traffic sound barriers

- Fence post and pickets

- Pallets

- Shipping containers

- Playground equipment

- Site amenities